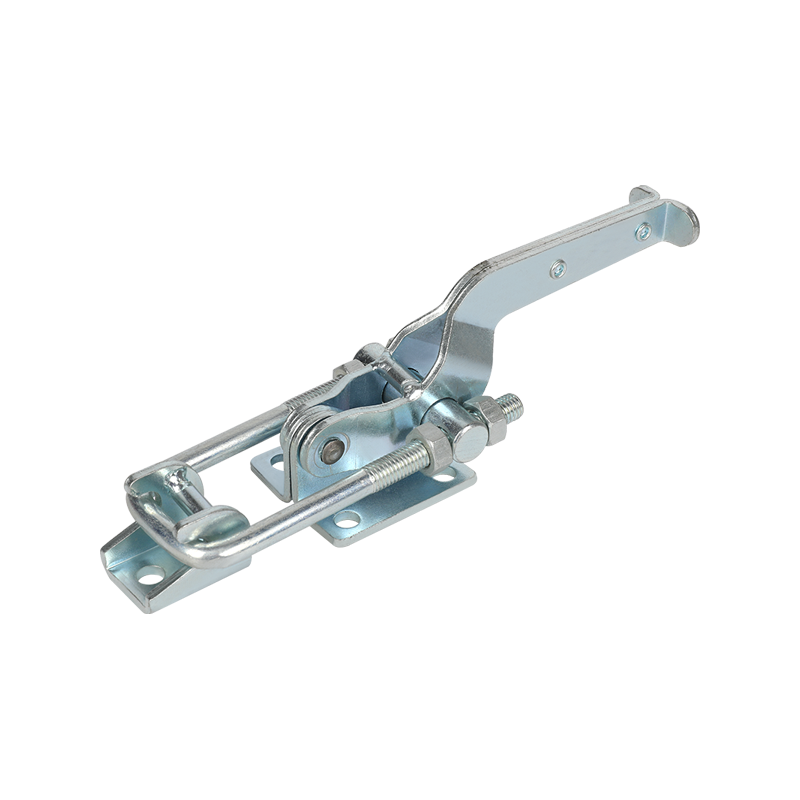

How does the lever clamp arm design of the Vertical toggle clamp ensure that it can adapt to workpieces of different sizes and shapes?

The lever clamp arm design of the Vertical toggle clamp ensures that it can adapt to workpieces of different sizes and shapes through several key elements:

Adjustability principle:

Vertical toggle clamps usually have an adjustable function, allowing users to adjust the position or angle of the lever clamp arm according to the size and shape of the workpiece. This adjustability allows the clamp to flexibly adapt to workpieces of different sizes.

Clamping force adjustment:

The design of the lever clamp arm allows users to adjust the clamping force through simple operations such as rotation or sliding. In this way, users can set the appropriate clamping force according to the specific needs of the workpiece (such as weight, shape and processing requirements) to ensure that the workpiece remains stable during processing.

Application of positioning elements:

Vertical toggle clamps may be equipped with positioning elements, such as pins, positioning pins, etc. (Reference article 2). These positioning elements cooperate with the positioning holes or surfaces on the workpiece to ensure that the workpiece can be accurately positioned in the clamp. This positioning accuracy is essential to adapt to workpieces of different shapes.

Material selection and structural reinforcement: To ensure that the clamp can meet the challenges of various sizes and shapes of workpieces, manufacturers usually choose high-strength and durable materials to manufacture the lever clamp arm and other key components. In addition, the design of the structure will be optimized to withstand the stress and load brought by different workpieces.

Modular design: Some advanced Vertical toggle clamps may adopt a modular design, allowing users to replace or add different clamping modules or accessories as needed. This modular design makes the clamp more flexible to adapt to various workpiece types and processing needs.

Practical application and feedback: When designing and producing Vertical toggle clamps, manufacturers usually consider the needs and feedback in practical applications. They will continuously optimize the design and function of the clamp based on user experience and usage to ensure that it can better adapt to workpieces of different sizes and shapes.

The lever clamp arm design of the Vertical toggle clamp ensures that it can adapt to workpieces of different sizes and shapes through key elements such as adjustability principle, clamping force adjustment, application of positioning elements, material selection and structural reinforcement, modular design, and practical application and feedback. These design features make the Vertical toggle clamp one of the indispensable clamps in various manufacturing and processing fields.

English

English Español

Español русский

русский