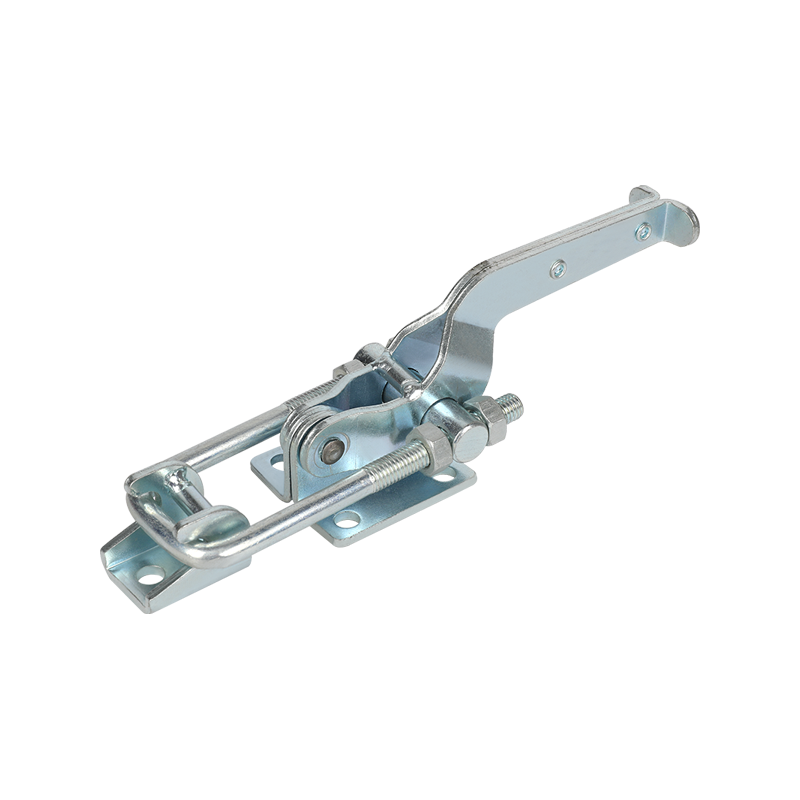

In the field of industrial automation and mechanical manufacturing, horizontal toggle clamp is an important clamping tool, which is widely used in various production lines and processing equipment. Its efficient clamping capacity and flexible adjustability enable the workpiece to remain stable during the processing, thereby improving production efficiency and product quality. Among them, the hinge design, especially the design of the rotating shaft or shaft column, is undoubtedly the key to the horizontal toggle clamp to realize its function.

The hinge design of the horizontal toggle clamp usually includes one or more rotating shafts or shaft columns, which play a vital role as a bridge connecting two or more parts (such as connecting the base frame and the movable connecting frame). They not only have to bear the weight of the workpiece and the fixture itself, but also have to deal with various forces and vibrations generated during the processing. Therefore, the design of the rotating shaft or shaft column is particularly important.

The first thing to consider in the design of the rotating shaft or shaft column is its load-bearing capacity. They need to be able to withstand the vertical pressure from the workpiece and the fixture, as well as the lateral tension caused by the change of the shape and size of the workpiece. In order to ensure sufficient load-bearing capacity, the shaft or shaft column is usually made of high-strength, wear-resistant materials such as stainless steel, carbon steel or other alloy materials. These materials not only have excellent mechanical properties, but also can maintain stable performance in harsh working environments.

In addition to load-bearing capacity, the design of the shaft or shaft column also needs to consider its rotation smoothness and precision. To achieve this, the surface of the shaft or shaft column usually needs to be precisely machined and specially treated to reduce the friction coefficient and improve wear resistance. At the same time, the fit between the shaft or shaft column and the connecting parts also needs to be accurately calculated and tested to ensure that the gap and tolerance between them are within a reasonable range, so as to achieve smooth rotation and precise positioning.

In the design process of the shaft or shaft column, some other factors need to be considered. For example, the shape and size of the workpiece will affect the layout and size selection of the shaft or shaft column; the clamping force requirements determine the stiffness and strength requirements of the shaft or shaft column; and the special requirements of the processing environment (such as temperature, humidity, corrosive gases, etc.) will put higher requirements on the material selection and surface treatment of the shaft or shaft column.

The hinge design of the horizontal toggle clamp, especially the design of the shaft or shaft column, is a complex and delicate process. It needs to comprehensively consider multiple factors such as load-bearing capacity, rotation smoothness and accuracy, workpiece shape and size, clamping force requirements, and processing environment. Through precise calculation, testing and optimized design, it can be ensured that the shaft or shaft column has sufficient load-bearing capacity, smooth rotation performance and precise positioning accuracy, thereby meeting the needs of the horizontal toggle clamp in various application scenarios.

English

English Español

Español русский

русский