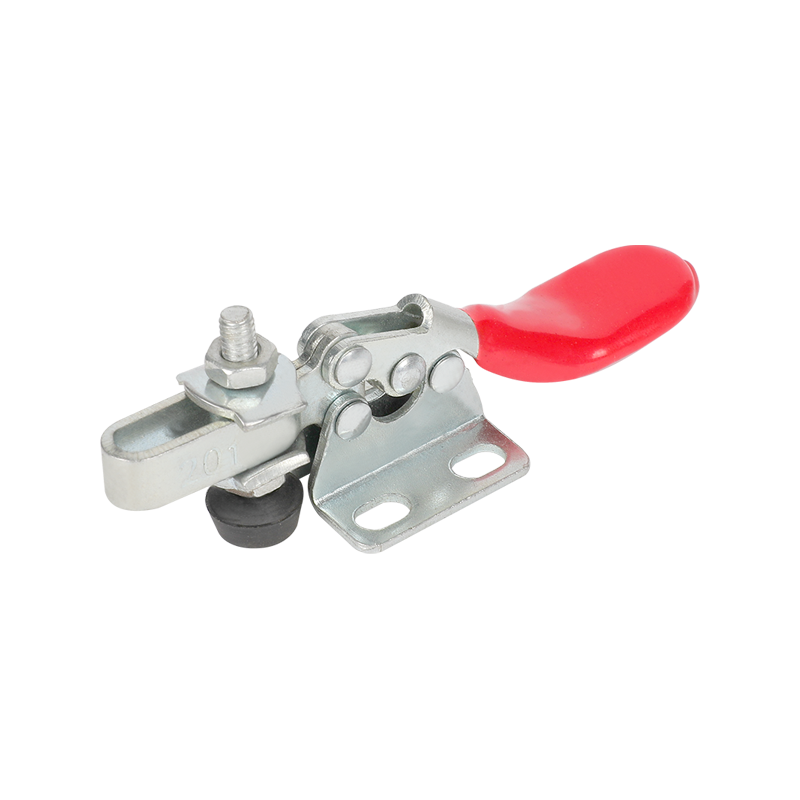

250*120mm forged F clamp with T-handle All-steel screw clamp is a high-quality tool that combines durability, stability and ease of operation. It can play an important role in both factory workshops and home DIY projects.

1. All-steel design, durable and reliable

This 250*120mm forged F clamp is made of all-steel material, ensuring extremely high durability and strength. Compared with traditional cast iron clamps, the all-steel structure clamp has better deformation resistance, can withstand greater pressure, and has a greatly extended service life. Even in a high-load operating environment, it can still maintain a good clamping effect and provide reliable support for the workpiece.

2. Forging process to improve clamping force

This clamp adopts advanced forging technology, and after precision machining and heat treatment, every detail of the clamp is strictly controlled to ensure its strong clamping ability. Compared with cast fixtures, forged fixtures have higher density and stronger mechanical properties, which can provide more stable and lasting clamping effect, thereby improving work efficiency and operational safety.

3. T-handle design, easy operation

The T-handle of the fixture is a highlight of this tool. The T-handle is not only convenient for users to grasp, but also provides better operation control under large torque conditions, reducing the burden on users' hands during use. Whether in a complex working environment or in long-term continuous operation, the T-handle can help users easily adjust the clamping force of the fixture, making work easier and more efficient.

4. Multiple applications, widely applicable

The 250*120mm forged F fixture with T-handle all-steel screw fixture has high applicability and is suitable for woodworking, metal processing, maintenance and other fields. Whether it is wood splicing, metal welding, or fixing other materials, it can provide precise and stable clamping effects to help professionals complete various process operations. In addition, its size (250mm x 120mm) is suitable for fixing small and medium-sized workpieces, which can meet the needs of most workplaces.

5. Maintenance and Care

In order to ensure that the clamp remains in good condition for a long time, it is recommended that users regularly check the threaded parts and chuck parts to avoid wear or rust caused by long-term use. For metal clamps, anti-rust oil can be applied in time to reduce the risk of oxidation and corrosion. In addition, keeping the clamp clean and dry is also the key to prolonging its service life.

English

English Español

Español русский

русский